RTM

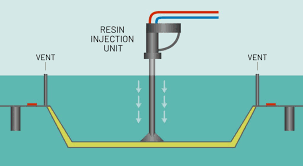

Resin transfer Moulding (RTM) RTM is a low pressure and low-temperature method of transferring a liquid thermoset resin into a closed Mould, which offers a dimensionally accurate and high quality of surface finish of composite.

Resin transfer Moulding (RTM) is the designation for a technology where, in general, a fiber preform is placed in a female Mould, the male Mould closes leaving a gap to allow resin to be injected and to impregnate the fibers.

RTM is one of the technologies used in aerospace industry Has shown to be capable of producing high quality components complex geometric shapes dimensional accuracy consistent with good makeup

RTM usually uses and aluminum close Mould the RTM process involves hand lay up on the mold then the mold is closed heated and placed under a vacuum in order for the reason to uniformly permit with the fiber finally reason is injected into the mold and held until the resin is cured

VARTM

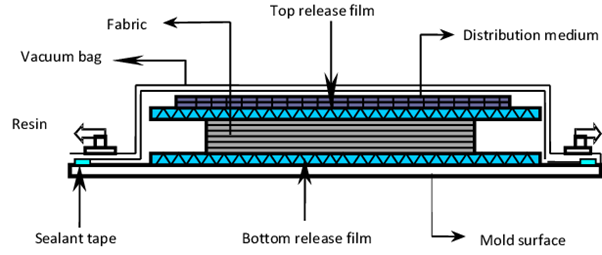

Vacuum assisted resin transfer Moulding can cover a lot of bases but typically is describe the process like vacuum infusion, but, where instead of bag there is a second hard or semi rigid tool dry fiber is laminated in one or both of the tooling and then resin is infused into the cavity using the atmospheric pressure only.

VARTM is different from RTM as it uses much more pressure and requires tools to be very heavy