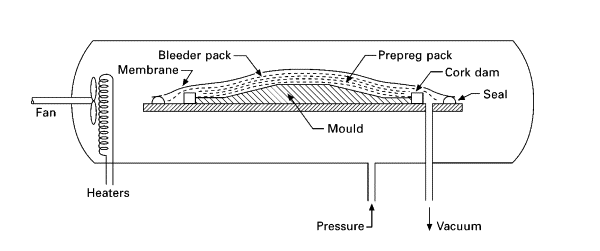

Autoclave Moulding

Autoclave Moulding is the process of manufacturing plastic parts where the parts are heated to a high temperature and pressurized steam is used

A typical autoclave-Moulding machine consists of three major sections – the heating section, the injection section and cooling section. The heating section heats up the plastic material to an elevated temperature injects it into a Mould into injection section. The injected materialized and cool down by air or water in the cooling section.

The time taken for each cycle can vary depending on different factors such a size of the product type of the product etc.

The autoclave Moulding process give few advantages such as better inter layer edition good control of both fiber and reason proper and sufficient fiber wedding degree of uniformity in component solidification used to manufacture high strength to weight ratio parts