Filament Winding

Filament winding is a manufacturing process for producing continuous length of filament or thin strands of material.

This technique is primarily used to manufacture hollow circular or prismatic parts such as pipe and tank

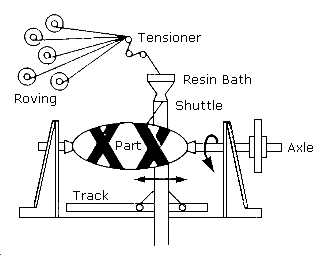

The process starts with a spool of raw material add a winding machine, which feeds the material through the machine and wines it on towards pool. The raw materials are usually plastic pallets that are melted and extruded into filaments Ben extruder. The filament, which is still in its molten state, is that drawn out of the extruder nozzle buy a drive mechanism search as vacuum or air pressure. The overall size and shape of the finished part are determined by the and mandrel shape and thickness of the laminate

There are 2 types of winding process wet winding and dry winding. Invite winding the fibers are unbound from roving and passed through a bath of Raisin mixture that is impregnation before it is bound on a mandrel of defined orientation. Dry method uses fibers in there free impregnated form during curing cross linking occurs and thus forms 3D network fibres

Filament winding machines can be large enough to fill an entire warehouse or small enough to fit on a desktop

Filament wound parts are commonly used in aerospace energy, and consumer product industries