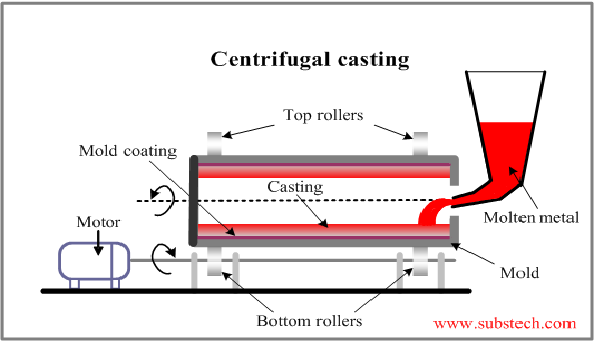

Centrifugal Casting

Centrifugal casting is a metal casting process that has been around for more than 100 years it is also one of the most popular casting processes

The process starts with molten metal being poured into a Mould. The mold is then spun at high speeds, which creates centrifugal forces that cause the metal to be drawn out and away from the side of the Mould. The interior surface of the centrifugal cast parts can be given additional coating of neat or pure resin to improve surface appearance and provide additional chemical resistance.

Composite pipes and tanks are commercially produced by centrifugal casting

Advantages of centrifugal casting include a finished Exterior surface and containment of volatile during processing.